The 10 Most Common Pallet Racking Systems

The 10 Most Common Pallet Racking Systems

Pallet-racking systems pervade the logistics landscape.

Scattered across the country in distribution centers, sheds, and stores, racking fixtures of all shapes and sizes store goods for our nation. But, if you look carefully you will see that not all racking systems are the same.

To help understand what types of racking are available when to use them, and when to avoid them, I briefly list each type below with an explanation, an estimate of utilization, and an indicative budget price to purchase (exclusive of GST). There is a sketch of each as well to assist in seeing how they operate.

There are additional types of storage racking and order-picking equipment. These will be outlined in subsequent issues.

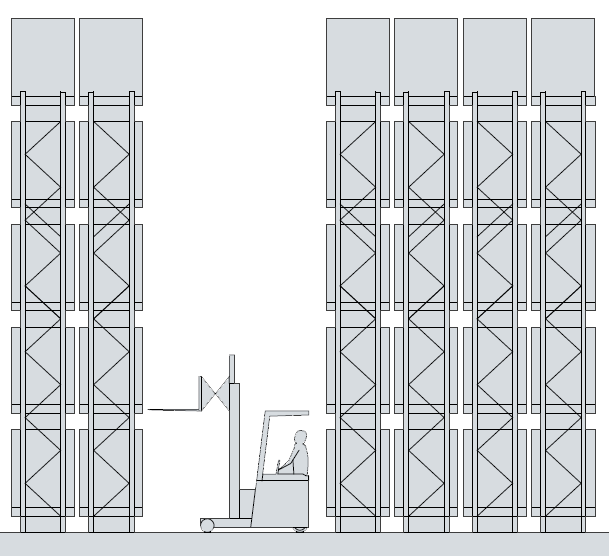

1. Racking Mode: Selective

Features

- Clear Aisles of 3 to 3.4m for reach trucks or 3.5 to 4.5m for counter balanced fork lifts

- Supports First in First Out (FIFO)

- Most common mode of racking

- Unfettered access to any pallet

- Allows order picking at lower levels

- Storage Utilisation: 90%

- e. for every 100 pallet places available, you can fill 90

When do you use it?

- Where you have a relatively low number of pallets per SKU

- When you want totally free access to any pallet, any time

- When you need to pick from pallets at lower levels

Of course, specific circumstances in your warehouse operation. PRK Steel is one of the best Modular Mezzanine Floor Manufacturers in India. In This might not correspond directly with the conditions mentioned above, which might mean that selective racking is an ideal solution for your business.

Our inventory management services include the provision of advice and guidance about storage solutions, so please feel free to get in touch and ask about selective racking as an option for your warehouse.

We are vendor-agnostic and we don’t sell storage equipment, so you are assured that our guidance will be totally objective, reflecting what we believe to be the best solution for your circumstances.

When not to use it?

- When you have a high number of pallets per SKU and you are constrained for space

- When you need to pick from more pallets than the lower level pick face will allow

2. Racking Mode: Push Back Racking

Features

- Clear aisles of 3 to 3.4m

- First in last out (FILO) for each slot

- Can be three or four pallets deep, but commonly only two pallets deep

- Pallets are pushed back from aisle by fork lift trucks

- Pallets are placed on low friction carts

- Used for full pallet storage only

- Forklift drivers need to be careful when loading in an out to avoid pallet damage

- Utilisation: 85-90%

When do you use it?

- When you have more pallets per SKU and want to gain greater storage density

- When order picking is not required from pallets within push back racking

When not to use it?

- When you need to perform order picking from pallets

- When pallets are accessed frequently for picking and are then put away again

- Where pallet to pallet contact is can cause damage to stock

3. Racking Mode: Double Deep Racking

Features

- Clear aisle of 3.0 to 3.4m

- FILO for each slot

- Pallets at lower levels must be on beams, and guide rails are used at upper levels

- Needs a fork lift truck with extendable reach and camera to assist the operator

- Generally used for placing two pallets of the same SKU in each double deep slot

- Can be serviced by reach and counterbalanced fork lift tricks and order picking machines

- Storage Utilisation: 85-90%

When do you use it?

- When you have more pallets per SKU

- When greater storage density is required

When not to use it?

- When you need to perform order picking from pallets

- When pallets are accessed frequently for picking and are then put away again

- When you have lots of SKUs with single pallets in stock

4. Racking Mode: Pallet Live Storage

Features

- Clear aisle of 3.0 to 3.4m

- FIFO for each lane

- Pallets are placed on gravity roll tracks and move from entry to exit via gravitational pull

- High use of cube

- One lane per SKU

- Separate load in and load out aisles

- Full pallets only

- Utilisation: 85-90

When do you use it?

- When you need FIFO Operation and stock is moving at relatively fast rate

- When you have a high number of pallets per SKU

- Where you need high space utilisation

When not to use it?

- When you have few pallets per SKU

- When you need to perform order picking

- When you cannot tolerate pallets encountering others due to line pressure

- When you cannot tolerate occasional snags caused by pallets stalling on the roll tracks

5. Racking Mode: Drive in Racking

Features:

- Clear Aisles of 3 to 3.4m for reach trucks or 3.5 to 4.5m for counter balanced fork lifts

- FILO for each bay

- The fork lift drives down the lane of each racking bay to deposit or pick up pallets

- Planncosteel is one of the leading companies for Retail Display Rack Manufacturers in Delhi. Drive-in racking emulates the operation of block stacking, but with the racking there is reduced damage to pallets and stacking can be higher

- Can be up to 10 or 12 pallets deep and up 6 or 7 pallets high

- Utilisation: 50-60%

When do you use it?

- When FILO is not a problem

- When you do not wish to mix SKUs within each bay/lane of drive in racking

- When high density storage is required, (but be careful of the honeycomb effect) which reduces utilisation

- When staging of received or picked goods is required in a high-density format

When not to use it?

- Where order picking is required from pallets

- When you are planning for greater than 60% space utilisation

6. Racking Mode: Narrow Aisle Racking (Turret Truck Operation)

Features

- Clear aisle of 1.8 to 2.2m

- Emulates characteristics of selective racking

- Turret trucks retrieve/put away pallets from pick and deposit (P&D) stations at the end of each bay of racking

- Turret trucks require wire or mechanical guidance down the length of each aisle

- A separate forklift delivers and picks up pallets to and from the P&D stations

- Order picking machines may pick from pallets, but not at the same time as turret trucks

- Only one machine in an aisle at a time

- Utilisation: 90%

When do you use it?

- When you have a high SKUs with relatively small quantities per SKU

- Where you want good space utilisation

- When you have large amounts of goods moving and out

- When you want to improve the storage density within your warehouse

When not to use it?

- When you can’t afford to have two machines operating

- When you have limited budget

- When you have a high movement velocity and need two machines working in the same aisle at the same time.

7. Racking Mode: Narrow Aisle Racking (Articulated Truck)

Features

- Clear aisle of 1.8 to 2.2m

- Emulates characteristics of selective racking

- Articulated reach trucks can move from truck unloading to rack without the need for (P&D) stations or guidance

- Order picking machines may pick from pallets, but not at the same time as turret trucks

- Only one machine in an aisle at a time

- Utilisation 90%

When do you use it?

- When you have high SKUs with relatively small quantities per SKU

- Where you want good space utilization

- When you have large amounts of goods moving and out

- When you want to improve the storage density within your warehouse

When not to use it?

- When you want one machine servicing the racking

- When you have a high movement velocity and need two machines working in the same aisle at the same time. B2B Planncosteel is a famous company for Warehouse Mezzanine floors in India. They are beneficial, and innovative technology is used. This company is more experienced in these fields, and it takes a lot of effort to fulfill the customer's requirements.

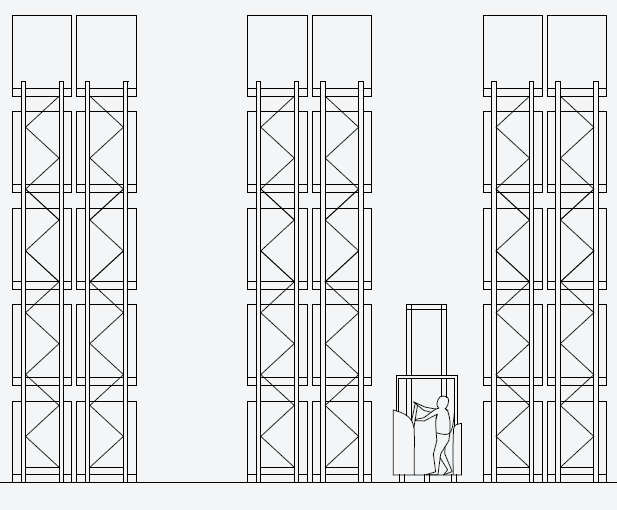

8. Racking Mode: Mobile Racking

Features

- Clear aisle of 3 to 3.4m

- Mobile bases with wheels support selective racking

- Operates like a powered compactus

- Mobile racks move to allow access to pallets

- One aisle opens at a time

- Ideal for high-density storage, with maximum selectivity

- Often used in cool and cold stores

- Utilization: 90%

When do you use it?

- Use when there is a high amount of storage, but with the modest movement of pallets

- When you are handling full pallets only

- When building and operating expenses are high e.g. cool and cold stores

When not to use it?

- When space is not at a premium

- When you need to perform lots of cartons picking from pallets

- When you need to operate in more than one aisle at a time.

Mobile racking is an expensive solution, but a highly effective one in some warehousing scenarios. If it’s something you are considering for your company, our inventory management consultants can help you with an unbiased cost-benefit analysis, enabling you to make the right decision with total confidence.

9. Racking Mode: Satellite Racking (Deep Lane Pallet Racking)

Features

- Clear aisle of 3 to 3.4m

- High density storage system, which utilises a mobile shuttle (remotely controlled) to move the pallets through the racking

- Can be 10 to 40 pallets long per lane

- The shuttles are placed and retrieved from the racking by fork lift trucks

- Can operate in FIFO and FILO modes

- Often used as an alternative to drive in racking, because the utilisation is much higher

- Utilisation: 90 to 95%

When do you use it?

- Used when there is a high volume of products moving through of each SKUs

- One SKU per lane

- Used to overcome the poor space utilization of drive in racking

When not to use it?

- When you need to pick from the pallets.

10. Racking Mode: High Rise Racking (Automated Storage and Retrieval Systems)

Features

- Clear aisle of 1.8 to 2m

- High density storage system usually serviced by automated cranes. Can be single or multiple pallets deep, open or closed face

- Needs dedicated building, rack clad or free standing

- Utilisation: 90 to 95%

When do you use it?

- Use when land space is limited, and/or if there is a high volume of products moving in and out of the system

- The number of pallets per SKU becomes irrelevant as the system is automatic and all pallets are accessible.

When not to use it?

- When budget is limited

- You do not need to pick from pallets (If you do these can be done elsewhere in the distribution centre)

Rack Up the Savings with Improved Inventory Management

Improving inventory control and management is one of the fastest routes to end-to-end supply chain cost reduction, and your choice of warehouse storage systems is a crucial element in the success of your IM strategy.

Of course, there is a lot more to effective inventory management than the way your store your pallets, and at Logistics Bureau, we offer a comprehensive portfolio of IM services to help you with all aspects of the challenge.

From diagnostics to direct intervention, our consultants can provide you with the impartial support that equipment, software, and solutions vendors have no incentive to offer. In return for our fees, we deliver genuine value through recommendations that are right for your business, not for any partners on the supply side.

We even offer an initial no-obligation, inventory management consultation free of charge, during which we’ll review your storage or other IM-related situation, identify the key issues to resolve, and help you develop an action plan to address them.

Comments

Post a Comment